-

Product Center

- Lanying R6000 Tiltrotor Aircraft

- Leiying Q20 Quadrotor Flight Platform

- T1200 Large Unmanned Helicopter

- TD550 Coaxial Unmanned Helicopter

- Q100 Agricultural UAV

- TD220 Coaxial Unmanned Helicopter

- TD5 Coaxial Unmanned Helicopter

- Design Techniques for Modification from Manned Helicopter to Unmanned Helicopter

- TA-Q12 Multi-Rotor UAV

- TA-Q3 Pipeline Patrol Mini UAV

- TA-Q4 Warehouse Patrol Mini UAV

- TA-Q5 Tunnel Patrol UAV

- Unmanned Helicopter Integrated Tester

- 28V Actuator Servo Driver

- Dual-Redundancy Electric Servo Actuator(Rotary Actuator)

- Dual-Redundancy Electric Servo Actuator(Linear Actuator)

- Smart Actuator

- 270V Dual-Redundancy Actuator Servo System

- Dual-Redundancy Servo Controller

- Multiple Redundant Flight Control Computer

/

- Solutions /

- Service and Support /

-

News Center

News Center

/

- About ZhongHangZhi /

- CN

- EN

- Product Center

-

UAV Products

- Lanying R6000 Tiltrotor Aircraft

- Leiying Q20 Quadrotor Flight Platform

- T1200 Large Unmanned Helicopter

- TD550 Coaxial Unmanned Helicopter

- Q100 Agricultural UAV

- TD220 Coaxial Unmanned Helicopter

- TD5 Coaxial Unmanned Helicopter

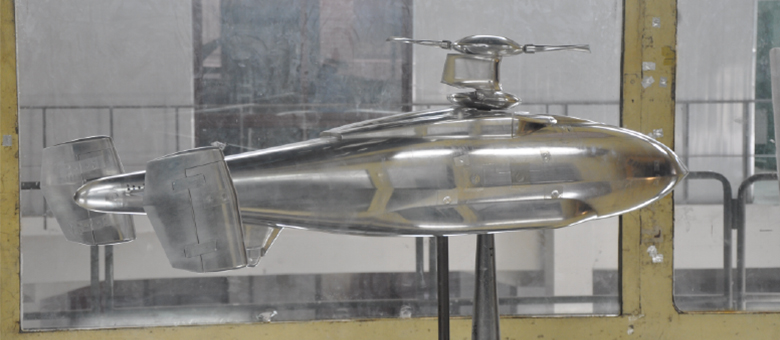

- Design Techniques for Modification from Manned Helicopter to Unmanned Helicopter

- TA-Q12 Multi-Rotor UAV

- TA-Q3 Pipeline Patrol Mini UAV

- TA-Q4 Warehouse Patrol Mini UAV

- TA-Q5 Tunnel Patrol UAV

-

Ground Equipment

- Integrated Logging Truck

- Unmanned Equipment Simulation Training System

- Ground Support Power Supply

- Life Support Shelter

- Vehicle-Borne/Ground Control Station

-

Airborne Equipment

- Unmanned Helicopter Integrated Tester

- 28V Actuator Servo Driver

- Dual-Redundancy Electric Servo Actuator(Rotary Actuator)

- Dual-Redundancy Electric Servo Actuator(Linear Actuator)

- Smart Actuator

- 270V Dual-Redundancy Actuator Servo System

- Dual-Redundancy Servo Controller

- Multiple Redundant Flight Control Computer

-

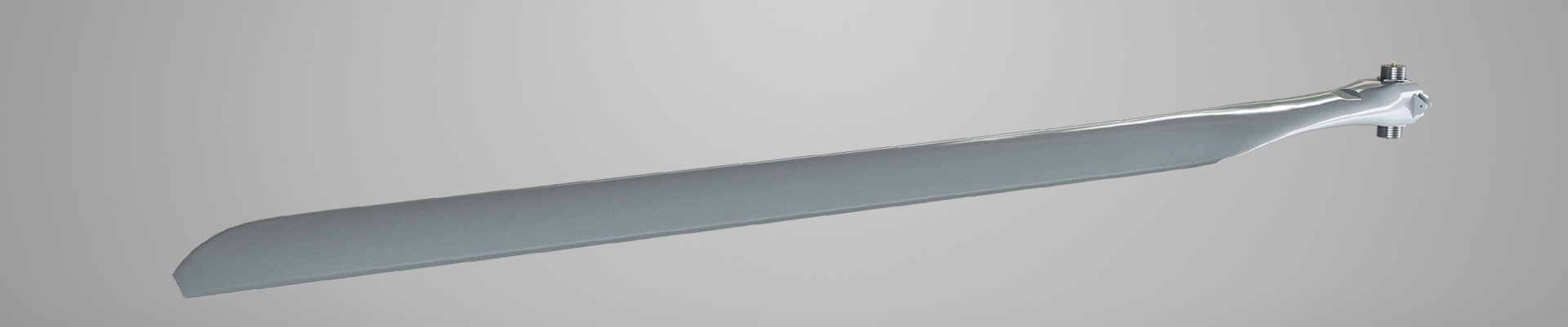

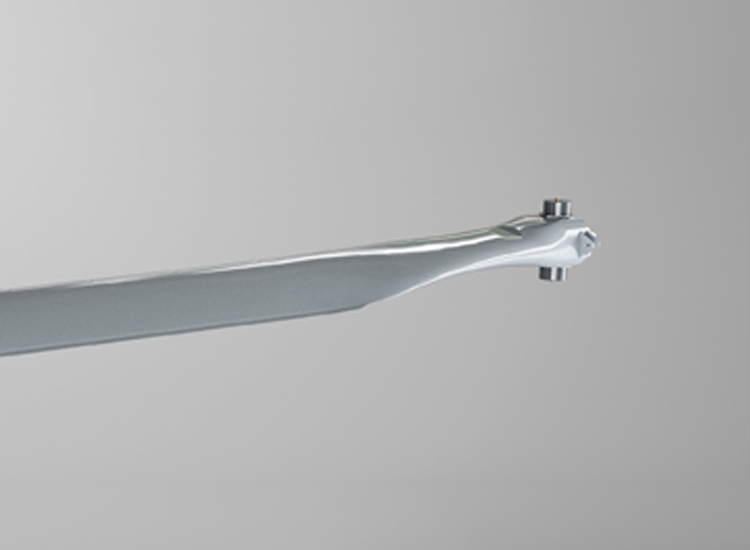

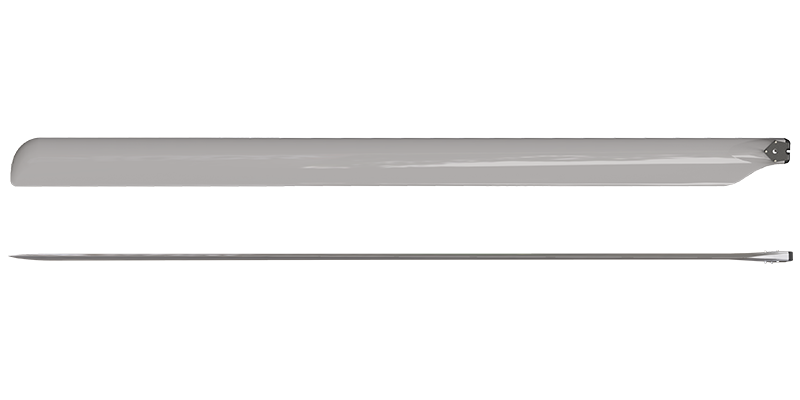

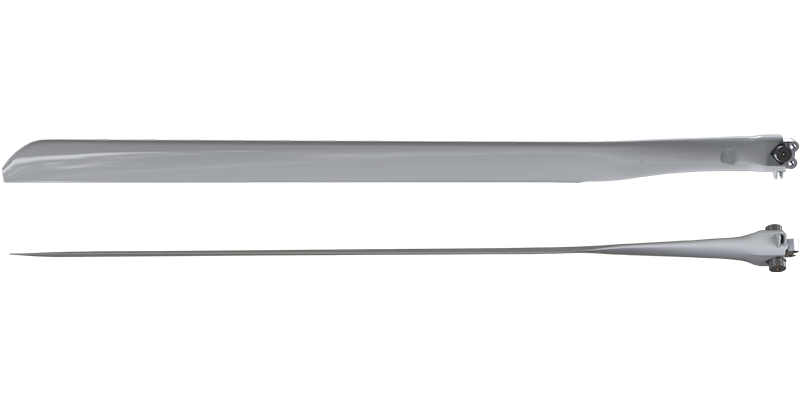

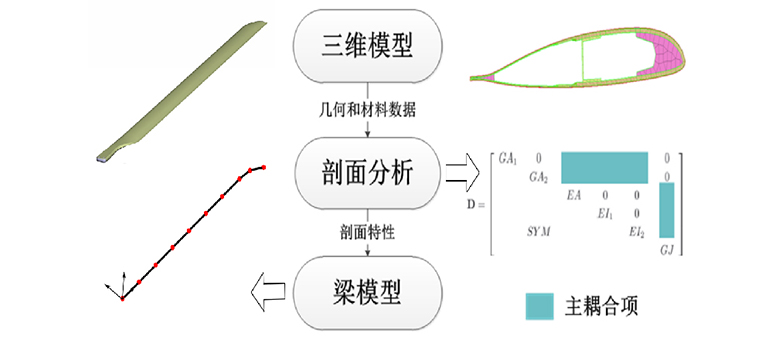

Rotor Blades

-

Composite Products

-

UAV Products

- Solutions

- Service and Support

- News Center

- About ZhongHangZhi